Centre for Sustainable Materials Processing

New paper on metal recovery from solar cells using DESs

Solar cells are a key technology for reducing carbon dioxide emissions. To achieve net-zero emission targets, a significant increase in solar energy production is needed. Increased production of solar cells will lead to an increasing demand for the raw materials that make them up: mainly silver, aluminium and silicon for crystalline solar cells, which represent 90% of the current market.

Solar cells are a key technology for reducing carbon dioxide emissions. To achieve net-zero emission targets, a significant increase in solar energy production is needed. Increased production of solar cells will lead to an increasing demand for the raw materials that make them up: mainly silver, aluminium and silicon for crystalline solar cells, which represent 90% of the current market.

However, the lifetime of solar cells is about 20 years, which means that a very large amount of solar cells will need to be recycled within this decade. It is estimated that 80 million tonnes of solar cell waste will be generated by 2050. Recycling of used solar cells is necessary to avoid landfill, but it also serves as a source of valuable materials that can be recovered; thus, avoiding metal "leakage" and associated pollution. Current recycling methods use harmful chemicals. Silver is removed from silicon with nitric acid, while aluminium is removed with concentrated sodium hydroxide.

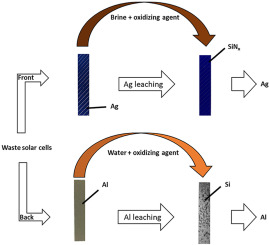

In this new article, we have developed an acid-free method to recover metals from solar cells. First, the aluminium layer is removed with aluminium chloride in water. The resulting solution can be used for wastewater treatment. Secondly, the silver is dissolved using iron chloride to oxidise the silver in a mixture of choline chloride (an ingredient normally used as chicken feed) in water. These unconventional brines have proven to be economically competitive with current hydrometallurgical methods and are promising tools for metal processing. After metal recovery, the remaining silicon wafer can be recovered to make new solar cells. We have therefore demonstrated a complete recovery of crystalline silicon solar cell materials using environmentally friendly, cheap and readily available chemicals.

Full reference paper

Guillaume Zante, Rodolfo Marin Rivera, Jennifer M. Hartley, Andrew P. Abbott. "Efficient recycling of metals from solar cells using catalytic etchants", Journal of Cleaner Productiont, 2022, 133552. https://doi.org/10.1016/j.jclepro.2022.133552

About the author of the article:

Dr. Guillaume Zante is currently working at the Material Centre as Research Associate as part of the Met4Tech project. His research focuses on the development of efficient and sustainable chemical processes for the management of electronic waste. He is currently using deep eutectic solvents for the recovery of metals from solar cells, X-ray protective materials, thermoelectric devices and smartphones.

Acknowledgements

This project has received funding from the UKRI Interdisciplinary Circular Economy Centre for Technology Metals, Met4Tech project (EP/V011855/1) the European Union’s Horizon 2020 research and innovation program under the Marie Sklodowska-Curie grant agreement number 101026159. The authors would also like to thank the Faraday Institution (Faraday Institution grant code FIRG027, project website https://relib.org.uk), and for funding this work.

Authors would like to thank Mr. G. Clark, Dr. P. Bird, and Mr. A. Cox for their help with SEM and ICP-MS experiments, and the University of Glasgow for providing the solar cell panels.