Centre for Sustainable Materials Processing

Current Research Projects

Faraday Institution funded project

Recycling of lithium ion batteries (ReLiB)

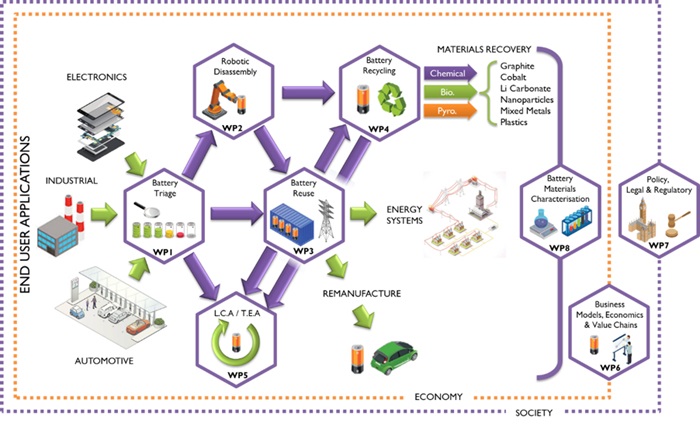

The Materials Centre at the University of Leicester is one of several UK Universities and industrial partners collaborating on research into facilitating a circular economy in lithium ion batteries.

The project aims to establish an infrastructure in which 100% of the materials found in lithium ion batteries used in the automative sector can be recycled. This will result in a significant impact on issues such as the safety, economics and efficiency of battery recycling, while also reducing the environmental impact incurred by these processes.

EU H2020 funded project

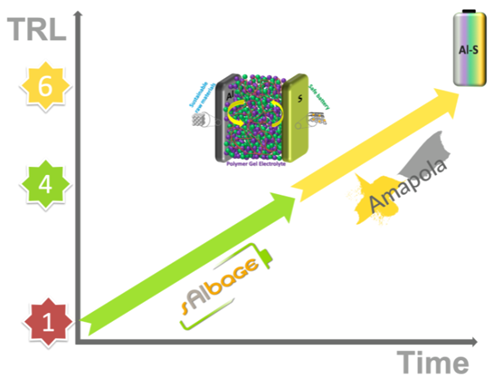

A Marketable Polymer based Al-S battery (AMAPOLA)

The Materials Centre, alongside ICTP-CSIC, TU Graz, TU Denmark, University of Southampton, are working with the world recognised battery company, Varta Innovation, and an SME expert in IPR management and transfer to market, Tech2Market, are further developing the research conducted by the EU H2020 Sulfur-Aluminium Battery with Advanced Polymeric Gel Electrolytes (SALBAGE) project.

Al-S batteries provide exciting possibilities for the future of battery technology. The abundance of both Aluminium and Sulfur make Al-S batteries an economically attractive option, and the Al-S cell has the capacity for very high energy storage. The AMAPOLA consortium are incorporating the use of innovative Polymer Gel Electrolytes (PGEs) based on novel highly conductive and inexpensive Deep Eutectic Solvents (DES) to create a cheaper, lighter, tougher and safer battery concept.

The project aims to further develop the materials proposed by SALBAGE, specifically the preparation of controlled phase-separated gel electrolytes from highly conductive novel DESs, the development of advanced cathode formulations, and the devising of strategies to overcome the presence of oxide layer at the aluminium anode. The consortium will also develop plans for up-scaling towards real application, and consider pre-industrialisation and marketing aspects.

UK Research and Innovation funded project

Circular Economy Centre for Technology Metals (Met4Tech)

The Materials Centre, alongside Professor Gawen Jenkin of the School of Geology, have teamed up with a cross-discipline group of leading international academic and industrial collaborators to work on improving and assuring the supply of raw materials, devising ways to manufacture goods to be re-used and recycled, and how to recycle complex goods such as batteries.

The Circular Economy proposes a revolutionary alternative to the traditional linear 'use and dispose' approach. The Circular Economy aims to maintain a continuous flow of resources at their highest value for the longest time period and then recovering, cascading and regenerating products and materials at the end of each life cycle. The Materials Centre Team are focusing on the development of novel separation and recycling techniques for technology metals.

It is hoped that the Met4Tech Centre will ultimately create a roadmap for an alternative technology metals circular economy system, including details of technology forecasts, strategic business models, new raw materials practices, and regulatory and governance requirements.